Daily Maintenance for Optimal Scrubber Machine Performance

Emptying and cleaning solution and recovery tanks

Empty and rinse both solution and recovery tanks after each use to prevent bacterial growth and chemical residue buildup. A 2022 facility maintenance study found tanks left uncleaned for over 24 hours develop 85% more pathogens. Pay special attention to inlet filters, where soap scum commonly accumulates.

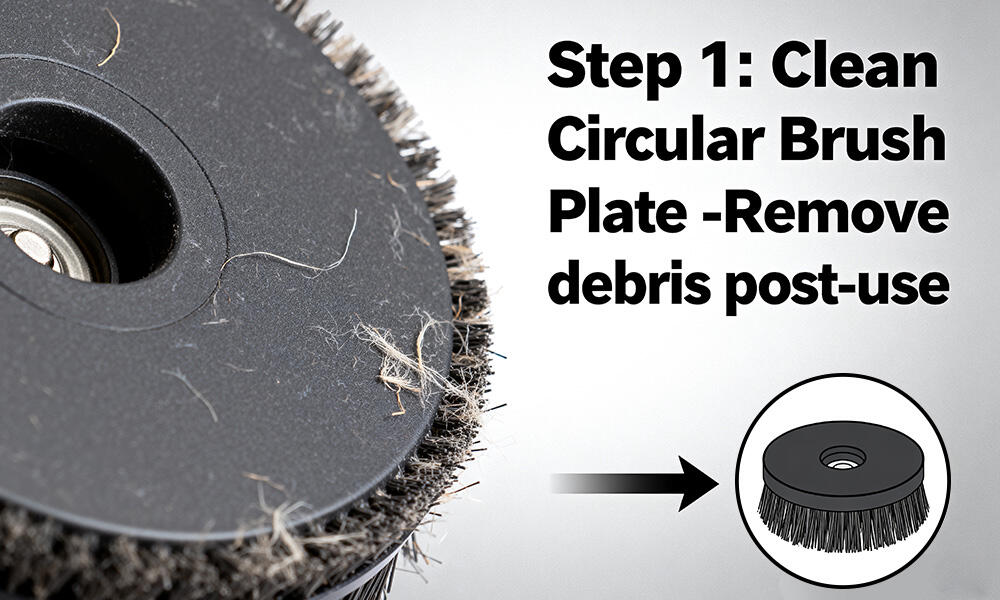

Inspecting and replacing brushes and squeegees daily

Worn brushes reduce scrubbing efficiency by 30–40%. Check bristle length against manufacturer specifications—most require replacement when worn below 1/4 inch (6 mm). Replace squeegee blades immediately if cracked, split, or curled, as damage compromises water recovery and leaves streaks.

Checking fluid levels in floor cleaning machines

Maintain solution tank levels between the minimum and maximum markers to avoid pump cavitation. Use only manufacturer-approved cleaning solutions, and test detergent concentration weekly with a refractometer—improper dilution accounts for 22% of premature pump failures.

Cleaning vacuum hoses and filters in scrubber machines

Clear debris from vacuum hoses after every use; partial clogs can reduce suction power by up to 60%. Tap out dry filters daily and wash reusable types weekly. Replace pleated filters when pressure gauges indicate a 15% or greater airflow restriction.

Performing quick inspection of debris trays and machine housing

Inspect for hair or debris wrapped around brush motors—the leading cause of bearing failure. Wipe down external surfaces with a damp cloth to minimize dirt infiltration through vents, and confirm all safety covers and access panels are secure.

Weekly and Monthly Preventive Maintenance Tasks

Facilities that follow structured weekly and monthly maintenance schedules experience 25–40% less component wear compared to those relying on reactive repairs. These routines sustain performance and extend equipment life.

Deep Cleaning Vacuum Systems and Recovery Tanks

Perform a thorough cleaning of recovery tanks and vacuum systems weekly using non-abrasive detergents to remove biofilm. Conduct a sanitization cycle monthly to minimize cross-contamination risks, especially in healthcare or food service environments.

Inspecting and Maintaining Brush Heads and Squeegees

Worn brushes reduce effective floor contact by up to 30%. Rotate brush heads weekly to promote even wear. Inspect squeegee blades monthly and replace any that show cracking or warping to maintain optimal water recovery.

Verifying Proper Suction Performance and Hose Integrity

Test suction strength weekly with a vacuum gauge. Inspect hoses for kinks, abrasions, or soft spots—minor leaks can reduce suction power by 15%, according to the 2023 Cleaning Equipment Efficiency Report.

Conducting Comprehensive Inspection of All Moving Parts

Conduct a full inspection of motors, bearings, wheels, and drive components monthly. Look for signs of misalignment, unusual vibration, or excessive noise. Facilities using manufacturer-recommended checklists report 22% fewer unexpected breakdowns.

Lubricating Joints and Checking Belt Tension in Scrubber Machines

Apply food-grade lubricant to pivot points monthly. Adjust drive belts to allow approximately ½ inch of deflection under moderate finger pressure—over-tightening increases motor strain by 18%.

Testing Electrical Connections and Control Panel Functions

Monthly checks of electrical terminals and control switches help prevent failures. Corroded connectors account for 34% of electrical issues. Perform resistance tests and ensure all buttons, indicators, and safety interlocks function properly.

Battery Care and Charging Best Practices for Scrubber Machines

Following Correct Charging Routines to Extend Battery Life

To preserve 30–50% of battery capacity over 3–5 years, charge batteries according to manufacturer guidelines. Use only approved chargers and avoid interrupting partial charges. For lithium-ion models, maintain charge between 20% and 80% for optimal longevity. During extended storage, keep batteries at a 50% charge level to reduce chemical degradation.

Monitoring Battery Water Levels and Terminal Corrosion

For lead-acid batteries, inspect water levels weekly and refill with distilled water just above the plates (about 1/4 inch). Clean terminals with a baking soda and water solution to remove corrosion, then apply dielectric grease to prevent future oxidation. Corroded terminals increase resistance by 42%, reducing runtime by 18%.

Scheduling Regular Load Testing for Electric Scrubber Machines

Perform load testing monthly to detect weak cells before they cause downtime. Measure voltage drop under simulated operating conditions—replace any cell showing more than 15% variance from baseline. Facilities with quarterly testing programs see 67% fewer unexpected battery failures.

Quarterly and Semi-Annual Deep Maintenance Procedures

Replacing Worn Brushes, Squeegee Blades, and Seals

Inspect high-wear components every 3–6 months to maintain peak performance:

| Component | Quarterly Check | Semi-Annual Replacement |

|---|---|---|

| Brushes | Measure bristle wear patterns | Replace if <8mm remains |

| Squeegee Blades | Check for cracks/tears | Install new EPDM blades |

| Tank Seals | Test water-tightness | Upgrade if leaks detected |

Conducting Full System Diagnostics on Pump and Valves

Use pressure gauges during operation to monitor pump performance. Deviations exceeding 15% from factory specifications may indicate cavitation, blockages, or seal failure. Service valves and check for internal debris or wear.

Inspecting Frame Integrity and Wheel Alignment

Check for stress fractures near load-bearing joints and loose fasteners in steering assemblies. Misaligned wheels impair cleaning consistency and accelerate tire wear—a 2mm misalignment can increase wear by 300% in ride-on models.

Reviewing Usage Logs to Predict Component Failure

Analyze 90-day usage logs to anticipate maintenance needs: track daily runtime for motor wear estimates, solution consumption per 1,000 sq.ft., and brush RPM trends. Facilities using predictive analysis reduce unplanned downtime by 61%.

Extending Scrubber Machine Lifespan Through Routine Care and Professional Servicing

Reducing downtime through routine maintenance to prevent breakdowns

Proactive maintenance reduces unplanned outages by 62% in commercial cleaning equipment. Simple daily checks—like fluid levels and brush condition—prevent cascading failures. Operators who document maintenance activities reduce repair costs by 34% compared to reactive approaches.

Following manufacturer-recommended service intervals

Adhering to OEM service schedules extends scrubber lifespan by 23%. These guidelines are tailored to specific wear patterns in drive motors, pumps, and brush decks. Ignoring them voids 78% of equipment warranties.

Scheduling annual professional servicing for complex components

Certified technicians perform advanced diagnostics using thermal imaging and vibration analysis to identify hidden issues in gearboxes and control boards. Factory-trained service ensures accurate calibration of critical systems:

| Component | Key Service Action | Frequency |

|---|---|---|

| Brush drive motors | Bearing lubrication & amp draw test | Annual |

| Solution pump | Seal replacement & pressure verification | Biannual |

Training operators on correct handling and shutdown procedures

Proper training prevents 81% of battery sulfation cases and 92% of hose clogs. Essential topics include avoiding curb impacts that warp alignment, correct battery watering techniques, and proper storage to prevent moisture damage. Consistent operator habits significantly improve machine reliability.

FAQ

Q: How often should I empty and clean the solution and recovery tanks of a scrubber machine?

A: It is recommended to empty and rinse both solution and recovery tanks after each use to prevent bacterial growth and chemical residue buildup.

Q: What routine checks should be performed on scrubber brushes and squeegees?

A: Inspect the bristle length of brushes daily and replace them if worn below 1/4 inch (6 mm). Squeegee blades should be replaced immediately if cracked, split, or curled.

Q: How can I maintain optimal battery life for a scrubber machine?

A: Follow the manufacturer's charging guidelines, use approved chargers, and avoid interrupting charges. For lithium-ion batteries, maintain a charge between 20% and 80% for longevity.

Q: What maintenance should be done weekly on scrubber machines?

A: Weekly tasks include deep cleaning vacuum systems, verifying suction and hose integrity, and testing suction strength. Utilize manufacturer-recommended routines for the best results.

Table of Contents

- Daily Maintenance for Optimal Scrubber Machine Performance

-

Weekly and Monthly Preventive Maintenance Tasks

- Deep Cleaning Vacuum Systems and Recovery Tanks

- Inspecting and Maintaining Brush Heads and Squeegees

- Verifying Proper Suction Performance and Hose Integrity

- Conducting Comprehensive Inspection of All Moving Parts

- Lubricating Joints and Checking Belt Tension in Scrubber Machines

- Testing Electrical Connections and Control Panel Functions

- Battery Care and Charging Best Practices for Scrubber Machines

- Quarterly and Semi-Annual Deep Maintenance Procedures

- Extending Scrubber Machine Lifespan Through Routine Care and Professional Servicing

- FAQ