Understanding the Risks of Floor Sweeper Operation

Common hazards associated with floor sweepers in industrial environments

Industrial floor sweepers come with their share of dangers. Workers can get caught in those spinning brushes, or run into things they didn't notice because nobody marked them properly. When floors are wet from cleaning, slips become a real problem too, especially around drain areas where water tends to pool. Looking at the numbers from safety reports, about one third of all incidents involve equipment problems like hydraulic fluid leaks or electrical system failures. And let's not forget about that mess accumulating around the bottom of machines either. This debris creates instability issues, making ride-on sweepers prone to tipping over when moving across rough factory floors or warehouse surfaces that aren't perfectly level.

Slips, trips, and falls due to wet or obstructed surfaces

The water based sweepers we see around warehouses tend to leave behind puddles and damp spots that become real trouble for workers walking through aisles and loading zones. When there are pallets scattered about, cables running across floors, or just general mess lying around, people start tripping more frequently. According to OSHA data from last year, places that don't have proper drying routines or warning signs posted end up seeing almost half again as many slips and falls compared to those with better protocols. Many facilities have found success by putting down retractable caution tape while cleaning is happening. This simple measure draws attention to wet spots and keeps folks from stepping into danger zones.

Mechanical and electrical risks from equipment malfunction

When there's an electrical short inside battery compartments, it can actually catch fire if there's any flammable dust around. And let's not forget about those frayed wires either they really do increase the chance someone might get shocked. Brush assemblies that get stuck tend to make motors run too hot, which often results in equipment shutting down when nobody expects it. The same goes for hydraulic systems in compactors failure here means loads dropping suddenly, sometimes causing serious damage. That's why checking all those little things matters so much seals need attention, connectors should be secure, and grounding systems must work properly. A good maintenance routine prevents most of these problems before they become real headaches down the line.

Why operator awareness is critical for floor sweeper safety

Operators who recognize hazards like low-hanging pipes or high-traffic intersections prevent up to 70% of avoidable incidents. Situational awareness enables quick responses to pedestrian movement or malfunction alerts. Familiarity with emergency stop locations and machine blind spots ensures timely intervention before minor problems escalate.

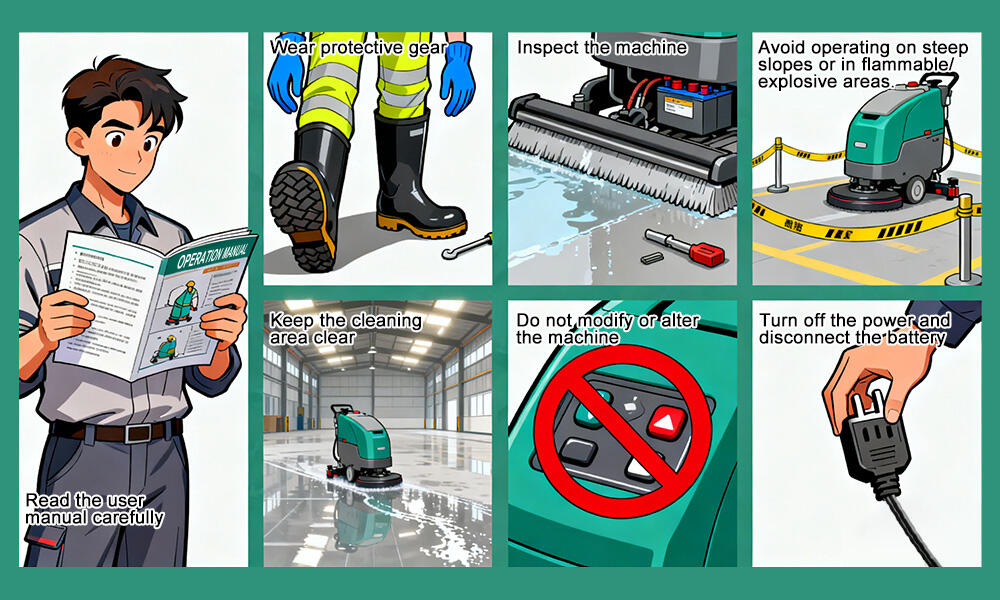

Conducting Pre-Operation Inspections and Equipment Checks

Essential pre-operational inspection steps for floor sweepers

Begin each shift with a systematic walkaround inspection to identify damage, debris, or obstructions near wheels and brushes. Test emergency stops and control panels for proper function. Operators who conduct daily inspections reduce mechanical failures by 34%, according to a 2023 equipment safety study.

Checking brushes, filters, battery, and hydraulic systems

Focus on four key systems:

- Brushes: Ensure bristles are intact and free of tangles

- Filters: Verify dust collection units aren’t clogged

- Battery: Check terminals for corrosion and confirm adequate charge

- Hydraulics: Inspect hoses for leaks or wear; verify fluid levels

Per MSHA Safety Services guidance, hydraulic checks should include pressure testing. Document all findings using checklists aligned with OSHA’s powered industrial truck standards.

Identifying leaks, loose components, and warning signals

Listen for unusual noises during a brief test run to detect bearing wear or motor strain. Look for:

- Fluid puddles under the machine

- Loose bolts on brush mounts or squeegees

- Frayed wiring near control modules

Do not operate equipment showing active warning lights or alarms—address issues immediately before use.

Using Proper PPE and Safe Work Zone Preparation

Required personal protective equipment (PPE) for floor sweeper operators

Operators must wear ANSI-certified, slip-resistant safety footwear—the leading cause of sweeper-related injuries being slips (25%, OSHA 2023). High-visibility vests enhance visibility in dimly lit warehouses, while cut-resistant gloves protect hands during maintenance. When working near energized components, arc-rated face shields compliant with NFPA 70E standards are required.

Footwear, high-visibility clothing, and hand protection guidelines

| Protection Type | Key Features | Industry Standard |

|---|---|---|

| Footwear | Steel toes, oil-resistant soles | ASTM F2413-18 |

| Clothing | 360° reflective strips | ANSI/ISEA 107-2020 |

| Gloves | Puncture-resistant palms | EN 388:2016 |

Composite toe shoes offer lighter weight for extended shifts, and moisture-wicking fabrics improve comfort in humid conditions.

Clearing debris, securing loose objects, and marking wet zones

Perform pre-shift walkthroughs to remove nails, plastic wrap, and other trip hazards. Use hydrophobic floor markers with at least 70% luminance contrast to clearly mark wet zones—42% of sweeper collisions occur near unmarked spills. Secure unstable pallet stacks using hazard assessment protocols designed for high-risk areas.

Setting up caution signage and managing foot traffic

Place bilingual warning signs with pictograms every 25 feet in cross-traffic zones. Stagger break schedules to reduce pedestrian congestion by 35–40% during peak cleaning times. Equip sweepers with rotating LED beacons to enhance visibility in narrow aisles under 8 feet wide.

Safe Operation: Maneuvering and Situational Awareness

Best Practices for Operating Floor Sweepers in High-Traffic Areas

Reduce speed by 30–40% in busy zones to lower collision risk without sacrificing efficiency. Establish visual communication using standardized hand signals, a method recommended in industrial safety guidelines to avoid miscommunication. Schedule sweeping during low-activity periods and clean aisles perpendicular to foot traffic to minimize path conflicts.

Navigating Wet or Slippery Surfaces Safely

When working on wet floors, it's important to adjust how hard the brushes press against the surface and control their speed. Too much force just pushes water around instead of cleaning properly and actually makes slips more likely. If there's standing water around, vacuum assisted sweepers work wonders, pulling out about 95 percent of the moisture as they go according to what we saw in the Industrial Cleaning Journal last year. Don't forget to switch on those slip resistant treads when operating ride on machines. And watch out for sudden turns too because these can throw off balance and cause problems down the line, especially on slick surfaces where stability counts most.

Ride-On vs. Walk-Behind Sweeper Safety Considerations

When operating ride on sweepers over rough terrain, operators need ROPS protection along with seat belts for safety reasons. Walk behind versions present different challenges though, mainly because their power cords can get tangled or snagged. These cords actually account for around 17 percent of all tripping accidents according to a report from the National Floor Safety Institute back in 2023. Newer ride on machines come equipped with special sensors that slow them down during tight corners, something walk behind models just don't have access to since they depend completely on whoever's pushing them to apply brakes manually.

How Modern Floor Sweepers Use Sensors and Collision Avoidance Tech

The latest equipment now comes equipped with infrared sensors alongside those 360 degree cameras that can spot objects down to around four inches away while the machine is moving. Operators get warnings through vibrations in their steering wheels almost instantly. Some of the newer models will actually halt movement automatically if someone steps within five feet of the vehicle, which makes all the difference in tight storage areas where visibility is limited. According to industry reports from last year, warehouses implementing these systems saw a drop of nearly two thirds in accidents involving sweepers and forklifts during just three years of operation.

Training, Maintenance, and Long-Term Safety Compliance

Operator Training and Certification Standards for Floor Sweeper Use

Formal training programs aligned with OSHA standards reduce accident rates by 54% in industrial facilities (National Safety Council 2023). Training must cover sweep patterns, emergency procedures, and safe battery handling. Leading sites require practical evaluations—such as obstacle courses simulating tight aisles and debris fields—before authorizing equipment use.

Developing Site-Specific Safety Training Programs

Tailoring training programs to tackle specific hazards at each facility makes all the difference. Take those greasy spots in warehouse corners or areas where forklifts cross paths with pallet jacks. Food processors often zero in on slip prevention around cold storage rooms since floors get slick from condensation. Meanwhile, auto plants worry about sparks flying in dusty environments where even a tiny spark could ignite something dangerous. When it comes to sweeper maintenance, these operations shouldn't exist in isolation but fit right into overall safety strategies. That means connecting daily cleaning routines with what happens during spills and how vehicles move through different zones throughout the day.

Implementing Refresher Courses and Routine Safety Audits

Conduct quarterly assessments using diagnostic metrics:

| Audit Focus | Key Metrics |

|---|---|

| Maneuvering accuracy | Clearance from racking (±2") |

| Debris recovery rate | Post-sweep particulate count |

| Battery safety | Terminal corrosion scoring |

Eighty-five percent of equipment-related incidents stem from outdated training (Industrial Safety Journal 2024). Address gaps through monthly microlearning sessions on emerging safety tech, such as LiDAR-assisted braking systems.

Proper Shutdown, Cleaning, and Storage Procedures After Use

Follow this 7-step protocol:

- Engage parking brake on inclines

- Power down brush rotation before raising

- Remove debris from undercarriage

- Wipe moisture-prone sensors with microfiber

- Charge batteries at manufacturer-specified voltage

- Store in climate-controlled areas below 104°F

- Lock ignition keys separately from machines

Adhering to this process prevents 92% of cold-start malfunctions linked to improper storage (Facility Maintenance Quarterly 2023).

FAQs

What are common hazards of using floor sweepers?

Common hazards include getting caught in brushes, colliding with unmarked objects, slipping on wet floors, and equipment malfunctions like hydraulic fluid leaks or electrical failures.

How can slips and trips be minimized?

To minimize slips and trips, ensure proper drying routines, use caution tape during cleaning, and place warning signs to draw attention to wet spots.

What PPE should floor sweeper operators wear?

Operators should wear ANSI-certified, slip-resistant footwear, high-visibility vests, and cut-resistant gloves. Arc-rated face shields are necessary when near energized components.

What pre-operational checks are necessary?

Pre-operational checks include inspecting for damage, debris, or obstructions, testing emergency stops, and ensuring the proper function of control panels.

How does modern technology enhance floor sweeper safety?

Modern sweepers use infrared sensors, 360-degree cameras, and collision avoidance technology to improve safety by detecting nearby objects and providing instant feedback to operators.