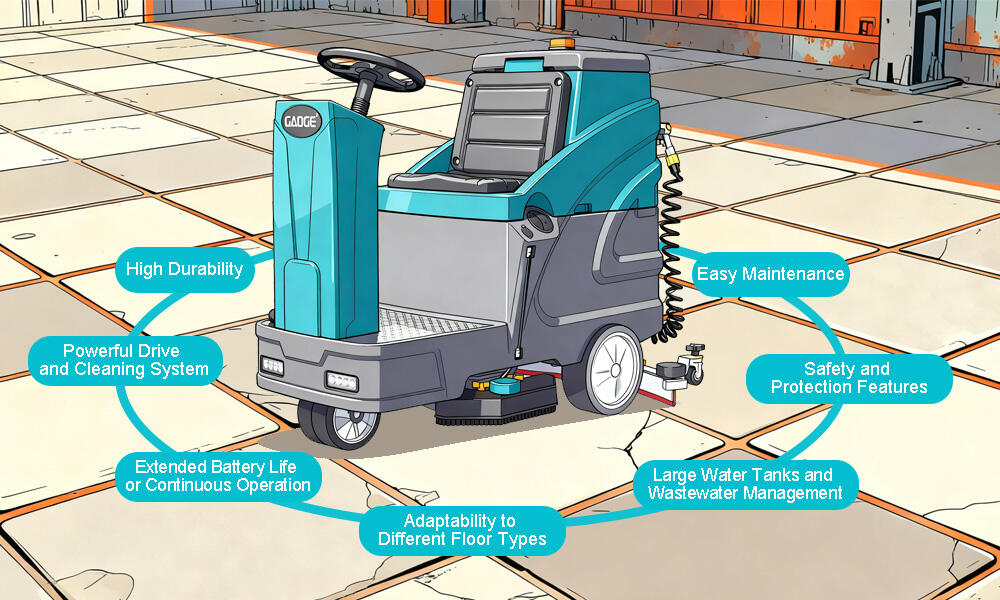

Durability and Build Quality for Demanding Industrial Environments

Reinforced chassis and corrosion-resistant materials in industrial floor scrubber construction

Most industrial floor scrubbers need sturdy frames made from steel alloys at least 12 gauge thick so they can handle all those bumps against pallets and heavy machinery during regular operation. Facilities that deal with harsh chemicals benefit greatly from corrosion-resistant coatings such as zinc nickel electroplating. These coatings really make a difference where there are acids or solvents around. According to recent research published in the 2025 Materials Durability Study, equipment treated this way lasts about 30 percent longer than regular models. That kind of durability saves money in the long run for maintenance shops and manufacturing plants alike.

Impact resistance and structural integrity under continuous operation

Modern units feature shock-absorbing polyurethane bumpers capable of absorbing 15,000+ impacts annually without frame deformation. Continuous operation testing reveals scrubbers maintaining 98% structural integrity after 5,000 hours in high-traffic warehouses—critical for 24/7 manufacturing plants.

Case Study: Long-term performance of heavy-duty industrial floor scrubber models in automotive plants

A three-year evaluation of 47 scrubbers in German automotive facilities showed models with reinforced pivot joints retained 85% of their original cleaning performance after 18,000 operating hours. Units lacking this feature required 40% more maintenance interventions, directly correlating with a 15% productivity loss in paint shop cleaning operations.

Trend: Increasing use of modular designs for easier maintenance and part replacement

Leading manufacturers now adopt clip-in brush modules and tool-free battery replacement systems, reducing downtime by 65% in food processing plants where daily washdowns accelerate component wear. This shift responds to industry demand for under-30-minute service windows in facilities losing £480/hour during cleaning equipment outages.

Strategy: Selecting materials based on facility-specific environmental stressors

| Environmental Factor | Material Solution | Performance Benefit |

|---|---|---|

| Chemical spills (pH <2) | 316L stainless steel housing | 90% corrosion resistance over 5 years |

| High-impact environments | Carbon fiber reinforced nylon | 40% better dent resistance vs aluminum |

| Extreme temperature swings | Thermal-stable polymer seals | Maintains integrity from -40°C to 80°C |

Facility managers report 28% longer equipment service life when conducting material compatibility audits before procurement, as per 2024 maintenance data from cold storage and foundry operations.

Cleaning Efficiency and Performance Standards in Industrial Applications

Achieving High Cleaning Coverage Rates With Advanced Brush and Suction Technology in Industrial Floor Scrubber Systems

Today's industrial floor scrubbers can cover almost all surfaces (about 98%) in just one pass thanks to clever designs such as overlapping brushes that spin around and suction ports that work from every direction. The machines pack quite a punch too, using over 1500 pounds per square inch of pressure along with motors that adjust speed depending on what needs cleaning. This helps tackle stubborn stuff stuck to floors like old grease marks and tiny bits of metal left behind after machining operations. When tested at actual food processing sites, these advanced scrubbers cut down leftover water on floors by roughly two-thirds when compared to older models without this special suction control feature. That makes a big difference for keeping walkways safe from slips, an especially important requirement in facilities under FDA regulations where safety standards are strict.

Measuring Performance: PSI, Scrub Width, and Solution Recovery Rates

Key metrics define industrial floor scrubber effectiveness:

| Metric | Industrial Standard | Warehouse Requirement |

|---|---|---|

| PSI Range | 800—2,000 | 1,200+ for oil stains |

| Scrub Width | 30—48" | 36"+ for aisles |

| Recovery Rate | ≥95% | ≥97% in freezer units |

A 2023 Logistics Cleaning Report found machines meeting all three benchmarks complete 28% more square footage per shift while using 19% less detergent.

Phenomenon: Mismatch Between Advertised and Real-World Cleaning Efficiency in Industrial Floor Scrubber Applications

Third-party verification reveals 41% of industrial floor scrubbers underperform OEM cleaning claims in production environments (IHSA 2024). Common discrepancies include:

- 22% lower chemical dispersion in sub-10°C temperatures

- 15% suction loss when handling >0.5" debris

- Brush wear causing 30% coverage reduction after 800 operational hours

Principle: Balancing Water Usage, Chemical Consumption, and Cleaning Speed

Leading facilities adopt the 3:2:1 ratio—3 gallons/minute flow rate, 2 oz/ft² detergent concentration, and 1 mph scrub speed. This optimized cleaning protocol cuts wastewater processing costs by $18,000 annually in automotive plants while maintaining OSHA-compliant surface friction ratings (≥0.5μ).

Compatibility with Harsh and Sensitive Operational Environments

Industrial floor scrubbers face unique operational challenges requiring specialized environmental adaptations. Let's examine three critical design considerations:

Adapting Industrial Floor Scrubber Functionality for Extreme Temperatures and Humidity Levels

Industrial floor scrubbers today need to keep working properly across pretty extreme temperatures ranging between minus 20 degrees Celsius all the way up to 50 degrees Celsius, which translates roughly to minus four Fahrenheit to around 122 Fahrenheit on the Fahrenheit scale. They also have to handle humidity levels going as high as 95%, though not when there's actual condensation happening. The big names in manufacturing tackle these challenges by incorporating special heated areas for batteries and electrical parts designed to wick away moisture. These components go through rigorous tests in harsh conditions before being approved for production. Such design choices are crucial because they stop problems caused by condensation buildup inside food processing facilities where cleanliness matters most, and they also keep things running smoothly in cold storage warehouses that operate below freezing point for extended periods.

Use of Explosion-Proof and ESD-Safe Industrial Floor Scrubber Variants in Sensitive Manufacturing Zones

In facilities handling flammable materials or static-sensitive electronics, industrial floor scrubbers require:

- ATEX-certified motors (Category 3 Zone 1)

- Grounded conductive brushes (surface resistance <10^6 Ω)

- Non-sparking wheel assemblies

These modifications reduce ignition risks in petrochemical plants by 73% compared to standard models (Industrial Safety Journal 2024).

Environmental Sealing and Ingress Protection Ratings for Reliable Operation in Wet or Dusty Facilities

Industrial floor scrubbers designed for cement plants and mining operations typically feature:

| IP Rating | Protection Level | Application Examples |

|---|---|---|

| IP65 | Dust-tight & water jetting | Automotive assembly plants |

| IP66 | Powerful water jets | Food/beverage processing |

| IP67 | Temporary immersion | Marine industry dockside use |

Units with IP67 certification can operate in 1m of water for 30 minutes while maintaining electrical safety compliance (EN 60529 standards).

Battery Life and Power Management for Continuous Operation

Extended Runtime Requirements for 24/7 Facilities Using Electric Industrial Floor Scrubber Fleets

Modern manufacturing plants require floor scrubbers capable of 8—12 hours of continuous operation. Facilities operating multiple shifts increasingly adopt industrial floor scrubber fleets with swappable battery systems, reducing downtime between charges. A 2023 Frost & Sullivan report shows warehouses using lithium-ion batteries achieve 22% higher daily utilization rates compared to traditional lead-acid models.

Advancements in Lithium-Ion Battery Integration for Industrial Floor Scrubber Units

New battery management systems (BMS) monitor cell-level performance metrics like voltage variance (±0.05V tolerance) and thermal fluctuations. Modular lithium packs now deliver 2,500—5,000 charge cycles—a 300% improvement over 2019 benchmarks. Top manufacturers have reduced full charge times to 90 minutes while maintaining 98% depth-of-discharge thresholds.

Trade-Offs Between Fast Charging and Battery Longevity in Industrial Floor Scrubber Operations

While rapid-charging solutions minimize equipment downtime, studies indicate frequent fast charging (>1C rate) accelerates capacity decay by 18—30% over 18 months. Leading operators balance these factors using adaptive charging algorithms that adjust rates based on battery temperature and state-of-charge.

Energy Efficiency and Regenerative Braking Systems in Modern Industrial Floor Scrubbers

Regenerative braking technology recovers 12—15% of kinetic energy during deceleration, extending daily runtime by 45 minutes in typical factory applications. Combined with brushless DC motors, these systems reduce total energy consumption by 35% compared to conventional scrubbers (DOE 2022 Energy Saver Program data).

Ease of Maintenance and Service Accessibility to Minimize Downtime

Design Features That Reduce Downtime in Industrial Floor Scrubber Maintenance Routines

The latest industrial floor scrubbers come with modular designs making it possible to swap components quickly without tearing everything apart. These machines have tool-free access to parts such as brushes, filters, and those annoying squeegee assemblies. Maintenance crews can finish their regular servicing tasks about 35% quicker than with older models according to Facility Maintenance Journal from last year. The convenience factor is huge when considering how busy facilities run around the clock. Things like pull-out battery compartments and those easy-to-detach hoses really matter for shops needing maintenance done within half an hour at most during continuous operation cycles.

Standardized Components and Diagnostic Systems in Modern Industrial Floor Scrubber Models

Many top manufacturers have started implementing consistent part numbers throughout their scrubber fleets, which cuts down on inventory headaches by around 40% at bigger plants. The newer models come equipped with built-in diagnostics that flash different colors when something's wrong, so techs can catch problems early on like failing pumps or worn seals before things get really bad. Real world data from maintenance departments indicates that having standard parts for cleaning gear saves roughly a quarter of the time spent fixing stuff compared to those old proprietary systems most companies used to rely on.

Remote Monitoring and Predictive Maintenance Integration in Smart Industrial Floor Scrubbers

Scrubbers connected to IoT systems send live performance updates to central monitoring screens, so facility managers can plan maintenance when needed instead of sticking to arbitrary time schedules. The smart algorithms that look at motor vibrations and how solutions flow through the system have cut down unexpected breakdowns by about 14% in pharma plants. Independent studies back this up too showing that these proactive maintenance approaches save roughly $18k each year on a single scrubber unit where they're used heavily.

Table: Maintenance Efficiency Improvements in Smart Scrubbers

| Feature | Downtime Reduction | Cost Savings/Unit/Year |

|---|---|---|

| Remote diagnostics | 22% | $7,200 |

| Standardized parts | 18% | $4,800 |

| Modular brush systems | 31% | $3,500 |

Frequently Asked Questions

What materials are used in industrial floor scrubbers to resist corrosion?

Industrial floor scrubbers often use steel alloys and may have zinc nickel electroplating coatings to resist corrosion, especially in environments with harsh chemicals.

How do modular designs benefit industrial floor scrubber maintenance?

Modular designs allow for easy replacement of parts like brush modules and batteries, reducing maintenance downtime significantly.

What is a common issue with OEM cleaning claims for industrial floor scrubbers?

About 41% of scrubbers underperform in real-world conditions compared to their advertised cleaning claims, often due to lower chemical dispersion and suction loss.

Why are lithium-ion batteries preferred for industrial floor scrubbers?

Lithium-ion batteries offer higher daily utilization rates and have longer charge cycles compared to traditional lead-acid batteries.

How do industrial floor scrubbers manage extreme temperature and humidity levels?

They use special heated areas for batteries and moisture-wicking designs to handle temperatures between -20 to 50°C and up to 95% humidity without condensation.

Table of Contents

-

Durability and Build Quality for Demanding Industrial Environments

- Reinforced chassis and corrosion-resistant materials in industrial floor scrubber construction

- Impact resistance and structural integrity under continuous operation

- Case Study: Long-term performance of heavy-duty industrial floor scrubber models in automotive plants

- Trend: Increasing use of modular designs for easier maintenance and part replacement

- Strategy: Selecting materials based on facility-specific environmental stressors

-

Cleaning Efficiency and Performance Standards in Industrial Applications

- Achieving High Cleaning Coverage Rates With Advanced Brush and Suction Technology in Industrial Floor Scrubber Systems

- Measuring Performance: PSI, Scrub Width, and Solution Recovery Rates

- Phenomenon: Mismatch Between Advertised and Real-World Cleaning Efficiency in Industrial Floor Scrubber Applications

- Principle: Balancing Water Usage, Chemical Consumption, and Cleaning Speed

-

Compatibility with Harsh and Sensitive Operational Environments

- Adapting Industrial Floor Scrubber Functionality for Extreme Temperatures and Humidity Levels

- Use of Explosion-Proof and ESD-Safe Industrial Floor Scrubber Variants in Sensitive Manufacturing Zones

- Environmental Sealing and Ingress Protection Ratings for Reliable Operation in Wet or Dusty Facilities

-

Battery Life and Power Management for Continuous Operation

- Extended Runtime Requirements for 24/7 Facilities Using Electric Industrial Floor Scrubber Fleets

- Advancements in Lithium-Ion Battery Integration for Industrial Floor Scrubber Units

- Trade-Offs Between Fast Charging and Battery Longevity in Industrial Floor Scrubber Operations

- Energy Efficiency and Regenerative Braking Systems in Modern Industrial Floor Scrubbers

- Ease of Maintenance and Service Accessibility to Minimize Downtime

-

Frequently Asked Questions

- What materials are used in industrial floor scrubbers to resist corrosion?

- How do modular designs benefit industrial floor scrubber maintenance?

- What is a common issue with OEM cleaning claims for industrial floor scrubbers?

- Why are lithium-ion batteries preferred for industrial floor scrubbers?

- How do industrial floor scrubbers manage extreme temperature and humidity levels?